Star-Planet Activity Research CubeSat

Mission Goal

A team of graduate researchers and ASU staff are working to develop a small space telescope with the mission of monitoring the flares and sunspot activity of M-type stars.

My Part in This

Opto-Mechanical Engineering:

I began by designing fixture assemblies to test batches of dichroic filters to identify the best ones for use in the CubeSat.

It was crucial that these mounting jigs held the dichroics precisely in the positions they would occupy during the mission,

as any deviation could result in suboptimal testing data.

The components I modeled and drafted were machined professionally by the ASU Machine and Electrical Shop

with adherence to Geometric Dimensioning and Tolerancing practices.

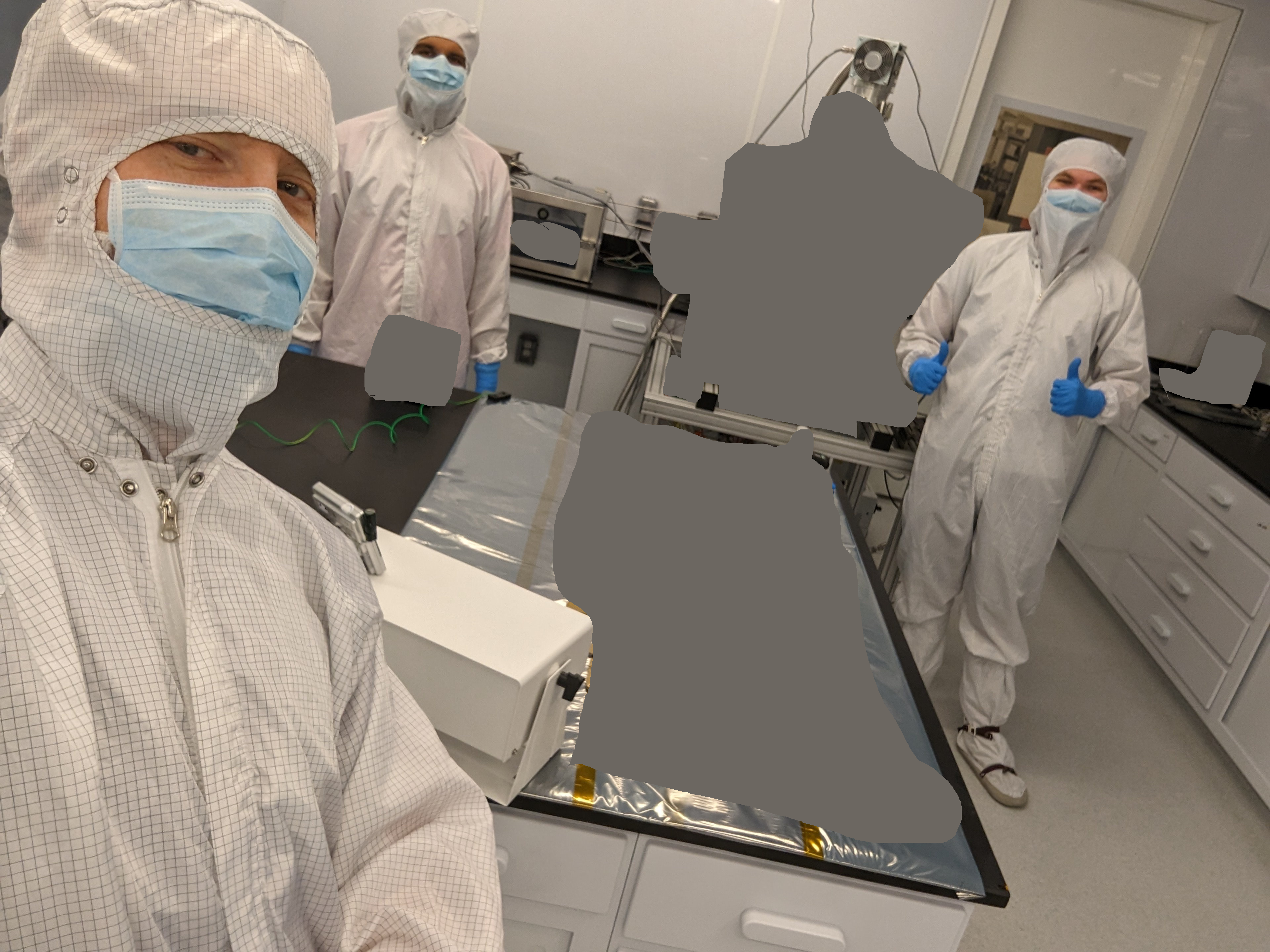

ISO-5 Cleanroom Experience:

At the point that I joined in the mission, most of the designing was already done or couldn't be started until other phases had been completed.

So I started assist more in the hands-on work of preparing and assembling different parts while inside the ISO-5 cleanroom. Initially,

this involved the cleaning of a lot of small parts like washers, screws, and so on. As I started to show that I could properly adhere to the clearnroom

protocols, I was allowed to assist in more significant operations such as the assembly of a thermal mass emulator.

As this work continued, Logan (my mentor) noticed that the vacuum chamber was showing more contaminants than there should be.

A converning development, since there were planned thermal tests on the horizon that required the use of the chamber.

Many attempts were made to fix this issue, but we ultimately had to resort to disassembling the entire structure so we could

clean it manually and reassemble everything while wearing the appropriate PPE in the cleanroom. This ended up solving the issue and the contimanants

were reduced back within acceptable levels.

With everything all good to go, we went through some extended-thermal testing to confirm the reliability of components purchased from another company.

To ensure good data, these tests had to last for more than 24 hours at a time and needed to be done over a period of multiple consecutive days.

This required the use of 8-hour shifts which went late into the night. I participated in two of these shifts to monitor a liquid nitrogen cooling loop

and adjusted parameters when necessary. It all went smoothly :)

My Thoughts

I thoroughly enjoyed my time volunteering on this mission. Getting to see how things are done on a professional level while still performing my undergraduate studies allowed me to gain perspective that I wouldn't have had otherwise. Not to mention the many great people I got to work with in this project. It was truly a joy to assist here, and I'm looking forward to the see the eventual launch and success of SPARCs!